A Load Cell is an electromechanical transducer designed to measure weight or force by converting mechanical load into an electrical signal. When integrated with a Programmable Logic Controller (PLC), load cells provide real-time and highly accurate weight data for automation processes.

They play a vital role in industrial weighing systems, batching, filling, and process monitoring, enabling precise control, reduced human error, and increased efficiency. The load cell works on the strain gauge principle, where applied force causes minute changes in resistance, producing a measurable electrical output. This signal is then conditioned and fed into the PLC for monitoring and control actions.

Built with robust materials like stainless steel or alloy steel, load cells are highly durable and suitable for harsh industrial environments. With a wide range of capacities (from a few grams to several tons), they are used in industries like food processing, pharmaceuticals, logistics, agriculture, manufacturing, and robotics.

By integrating load cells with PLCs, industries benefit from automated, accurate, and reliable weight-based control systems that enhance productivity, ensure quality, and support advanced process automation.

Description

A load cell is an electromechanical sensor that measures force or weight and converts it into an electrical signal. When integrated with a Programmable Logic Controller (PLC), load cells enable accurate weight monitoring, process automation, batching, and real-time production control. They are widely used in industries such as manufacturing, food processing, pharmaceuticals, and logistics where precise weight measurement is critical.

Specifications (Typical for Strain Gauge Load Cells)

-

Type: Strain Gauge Load Cell (Bridge Circuit)

-

Capacity Range: 1 kg to 100 tons

-

Output Signal: 1–3 mV/V (requires amplifier)

-

Excitation Voltage: 5–12 VDC

-

Accuracy: ±0.02% – ±0.05% of full scale

-

Material: Alloy Steel / Stainless Steel

-

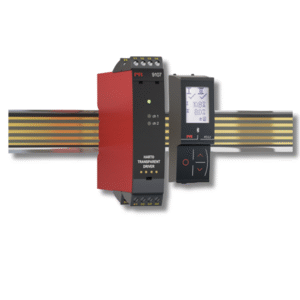

Interface with PLC: Via signal conditioning modules (e.g., HX711, Analog input modules, or dedicated weighing modules)

-

Operating Temperature: -10°C to +50°C (varies with model)

Key Features

✅ High accuracy weight measurement

✅ Compact and robust construction

✅ Easy PLC integration through analog or digital modules

✅ Wide load range (grams to tons)

✅ Long service life and reliable performance

✅ Compatible with automation systems (Siemens, Allen-Bradley, Mitsubishi, etc.)

✅ Overload protection design

Applications in PLC Systems

-

Industrial Weighing Machines (packing, filling, batching)

-

Conveyor Belt Systems (monitoring and controlling material flow)

-

Tank and Hopper Weighing (level control by weight)

-

Robotics & Material Handling (grip force measurement)

-

Quality Control Systems (checking product weight in production lines)

-

Automated Dosing Systems (food, pharma, chemicals)

Advantages

✔ High precision and reliability

✔ Can be easily automated with PLCs

✔ Reduces human error in measurement

✔ Suitable for dynamic as well as static load measurement

✔ Works in harsh industrial environments

✔ Increases process efficiency and productivity

Disadvantages

✖ Requires signal conditioning (raw mV output is very small)

✖ Sensitive to electrical noise if not shielded properly

✖ Can be affected by temperature variations

✖ Mechanical overload may damage the sensor

✖ Requires calibration for accurate measurement