GI Metal Hoses are flexible galvanized iron conduits designed to provide strong mechanical protection and reliable flexibility for electrical cables, fluids, and gases. Their galvanized coating ensures corrosion resistance, while their durable construction makes them suitable for industrial wiring, machinery, and heavy-duty applications.

Description

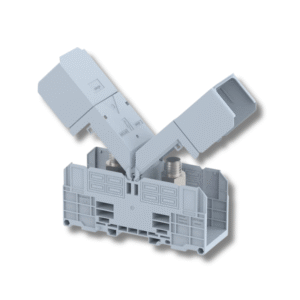

GI Metal Hoses are flexible galvanized iron conduits designed to provide strong mechanical protection and reliable flexibility for electrical cables, fluids, and gases. Their galvanized coating ensures corrosion resistance, while their durable construction makes them suitable for industrial wiring, machinery, and heavy-duty applications.

GI (Galvanized Iron) Metal Hoses are strong, flexible conduits designed for carrying fluids, gases, and protecting electrical cables. Manufactured from galvanized iron strips, these hoses provide durability, corrosion resistance, and mechanical protection, making them ideal for industrial and commercial applications.

Specifications

-

Material: Galvanized Iron (GI)

-

Construction: Interlocked / Squarelocked / Flexible corrugated design

-

Diameter Range: 12 mm – 100 mm (custom sizes available)

-

Length: Standard rolls (10 m / 25 m / 50 m)

-

Finish: Galvanized / Zinc-coated

-

Temperature Range: −20°C to +300°C (varies by application)

Features

-

High mechanical strength with flexibility

-

Galvanized coating for corrosion resistance

-

Protects cables from dust, moisture, and abrasion

-

Heat and flame-resistant

-

Easy to install with standard fittings

Applications

-

Electrical wiring protection in industrial plants

-

Cable management in power and control panels

-

Machinery and automation equipment

-

Plumbing and gas transfer (light-duty)

-

HVAC and fire safety systems

Advantages

Strong and durable compared to PVC conduits

Flexible yet provides good mechanical protection

Resistant to corrosion and environmental damage

Withstands high temperatures

Suitable for both indoor and outdoor use

Disadvantages

Heavier than PVC and plastic hoses

Can corrode if coating is damaged

Less suitable for highly corrosive chemical environments

Higher cost than standard flexible conduits