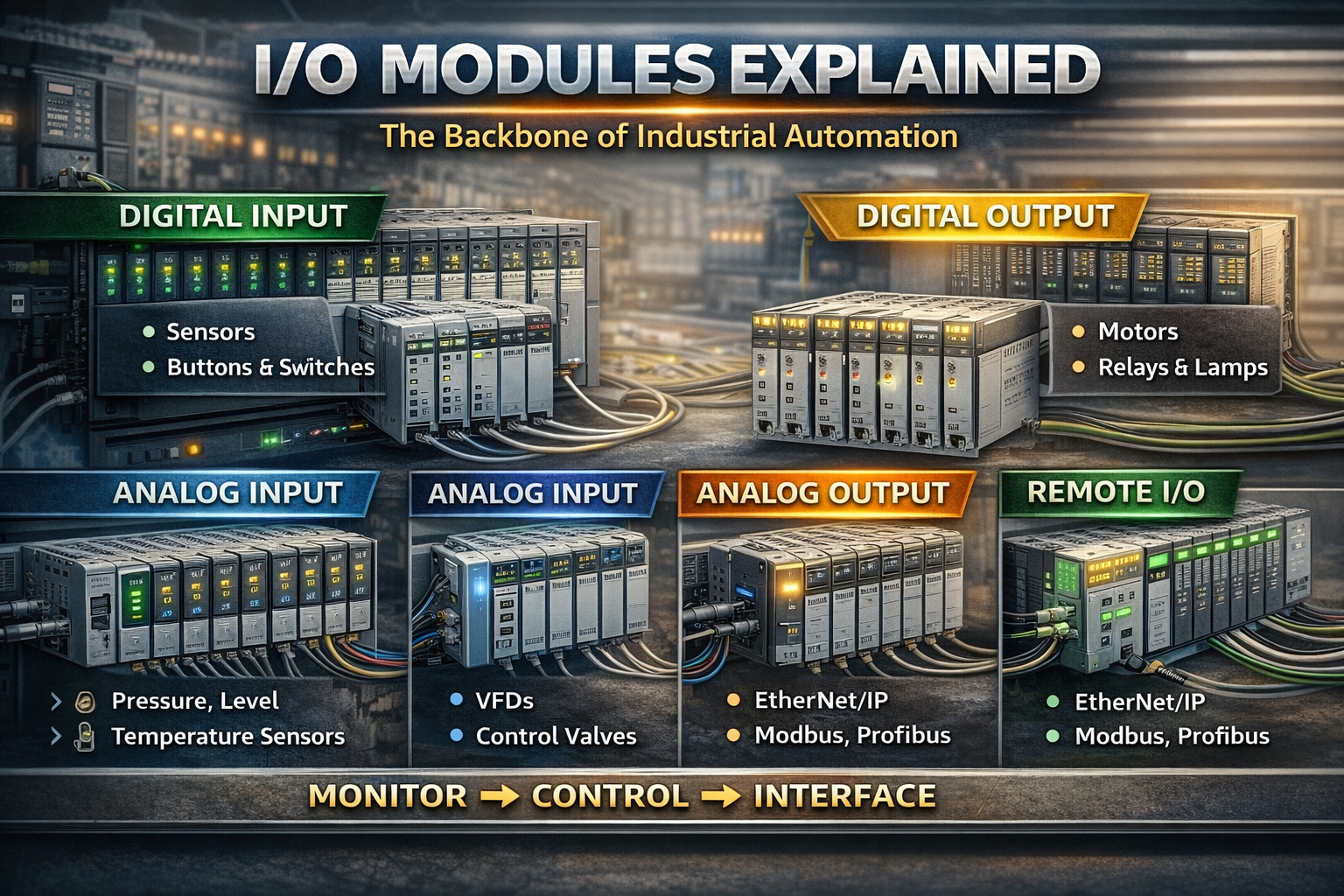

Types of I/O Modules in Industrial Automation

1. Digital Input (DI) Modules

Digital input modules read ON/OFF signals from field devices.

Common inputs:

-

Push buttons (Start / Stop)

-

Proximity sensors

-

Limit switches

-

Selector switches

Signal levels:

-

24V DC (most common)

-

110V AC / 230V AC (industrial panels)

Example:

If a proximity sensor detects a product, the DI module sends a logic “1” to the PLC.

2. Digital Output (DO) Modules

Digital output modules send ON/OFF commands from the PLC to field devices.

Common outputs:

-

Contractors

-

Solenoid valves

-

Indicator lamps

-

Relays

Output types:

-

Relay output

-

Transistor output

-

Triac output

Example:

When PLC logic turns ON a motor, the DO module energizes a contactor.

3. Analog Input (AI) Modules

Analog input modules read continuous signals from instruments.

Typical signals:

-

4–20 mA

-

0–10 V

-

RTD / Thermocouple (with dedicated modules)

Common instruments:

-

Pressure transmitters

-

Temperature sensors

-

Flow transmitters

-

Level sensors

Example:

A pressure transmitter sends 12 mA, which the PLC interprets as a specific pressure value.

4. Analog Output (AO) Modules

Analog output modules send variable control signals to devices.

Applications:

-

Speed control of VFDs

-

Valve position control

-

Heater power regulation

Example:

PLC sends 6 mA to control a valve at 30% opening.

Local I/O vs Remote I/O Modules

Local I/O

-

Installed inside the PLC panel

-

Short wiring distance

-

Suitable for small machines

Remote I/O

-

Installed near-field devices

-

Communicates via protocols like

-

Modbus

-

Profibus

-

Profinet

-

Ethernet/IP

-

Advantages:

-

Reduced cable cost

-

Faster installation

-

Better scalability

Why I/O Modules Are Critical for Machine Reliability

Proper selection and wiring of I/O modules ensures:

-

Accurate signal reading

-

Fast response time

-

Reduced noise and signal loss

-

Improved machine safety

-

Easier troubleshooting

Faulty or poorly selected I/O modules can cause:

-

False signals

-

Unexpected machine trips

-

Production losses

Common Industrial Applications of I/O Modules

-

Manufacturing automation

-

Power distribution panels

-

Water and wastewater treatment

-

Packaging machines

-

CNC and material handling systems

-

Process industries (chemical, pharma, cement)

Best Practices for Using I/O Modules

-

Match signal type correctly (AC/DC, analog range)

-

Provide proper grounding and shielding

-

Use separate power supplies for field I/O

-

Label I/O clearly in drawings and panels

-

Monitor I/O status via PLC or SCADA

Conclusion

I/O modules are the foundation of any PLC automation system. Whether digital or analog, local or remote, these modules ensure seamless communication between machines and control logic.

Understanding I/O modules helps engineers design reliable, scalable, and safe automation systems, reducing downtime and improving operational efficiency.