Natural Gas Control System for Craftsman Automation

At Mine Power, we specialize in designing and executing industrial automation and gas control systems that deliver safety, efficiency, and long-term reliability. One of our recent turnkey automation projects involved implementing a Natural Gas Control System for Craftsman Automation, a leader in advanced manufacturing and high-temperature furnace operations.

Project Overview

Craftsman Automation planned to upgrade from a conventional LPG-based heating system to a natural gas-fired furnace system to reduce operating costs and improve sustainability. This transition demanded a highly reliable gas control and monitoring system capable of ensuring precise flow control, real-time monitoring, and maximum safety.

Mine Power was entrusted with the complete automation design, supply, programming, and commissioning of the natural gas control system.

Natural Gas Control System Design & Implementation

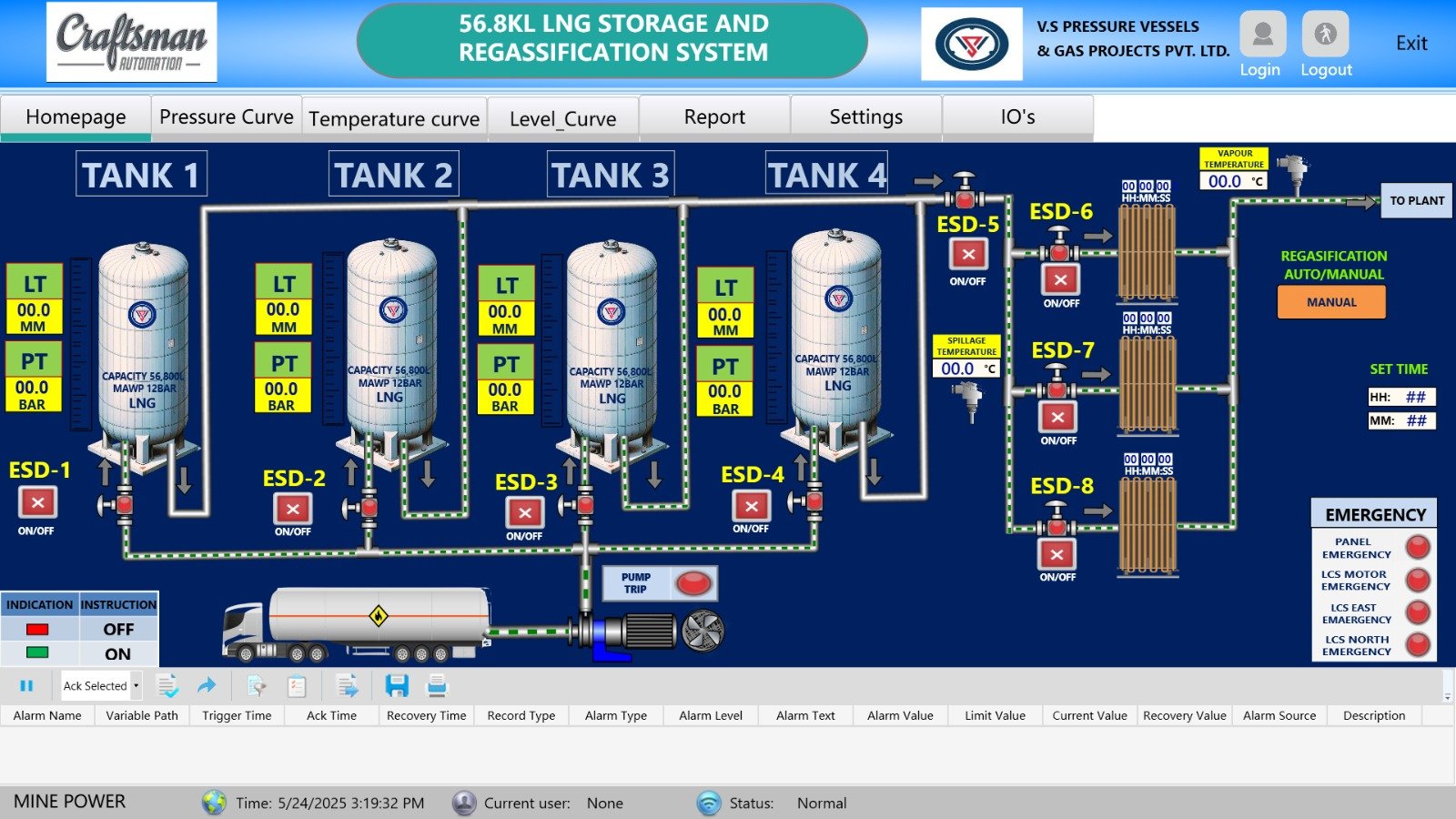

To ensure uninterrupted and safe gas supply, four natural gas storage tanks were installed on-site, each with a capacity of 60 kilolitres and operating at a working pressure of 8 bar.

The system was integrated with:

-

8 electronically controlled gas valves (24V DC)

-

Gas leakage detection sensors for enhanced safety

-

Pressure and temperature sensors for continuous monitoring

-

A fully automated PLC-based control architecture

Our engineers developed a Delta PLC and HMI-based automation system, programmed using ladder logic, to ensure accurate valve sequencing, interlocking, and emergency shutdown logic.

SCADA-Based Monitoring & Control

To provide complete operational visibility, Mine Power implemented a custom SCADA system tailored for natural gas applications.

Key SCADA features include:

-

Real-time pressure and temperature trending for all gas tanks

-

Visual and audible alarms for gas leakage or abnormal conditions

-

Historical data logging for analysis, audits, and diagnostics

-

Centralized control dashboard for operators and maintenance teams

This SCADA integration enables proactive decision-making and improves overall plant safety.

Key Benefits for Craftsman Automation

With the new Natural Gas Control System, Craftsman Automation achieved:

-

Enhanced operational safety through automated leak detection and interlocks

-

Improved energy efficiency with precise gas flow control

-

Reduced manual intervention via PLC and SCADA automation

-

Better process visibility using real-time data and historical trends

-

Reliable and scalable system architecture for future expansion

Trusted Industrial Automation Partner

Mine Power continues to support industrial leaders by delivering custom automation solutions, including SCADA systems, PLC panels, gas control systems, MCC & PCC automation, and turnkey industrial projects—engineered to meet the highest safety and performance standards.

Looking to Upgrade Your Industrial Gas Control System?

If you are planning to modernize your natural gas, LPG, or furnace automation system, our experts are ready to help.

👉 Get in touch with Mine Power today for a customized automation solution.

Do you need help? We’re here to support you.