A Counter is used in automation to count events, objects, or pulses and trigger actions when preset values are reached. Integrated with PLCs and sensors, counters are widely applied in production monitoring, batch control, conveyors, and machine cycle tracking, ensuring accuracy and efficiency in industrial processes.

Description

A Counter is a device (hardware or PLC software function) that counts events, objects, or pulses and then triggers control actions once a preset value is reached. In PLC systems, counters are commonly used for production counting, machine cycles, batch control, and process monitoring. They are available as standalone digital counters (panel mount) and as PLC programming instructions (CTU, CTD, CTUD).

Specifications

-

Input Signal: Pulse (from sensors like proximity, encoder, switch, or PLC digital input)

-

Display: 4–6 digit LED/LCD (for standalone counters)

-

Counting Modes: Up counter (CTU), Down counter (CTD), Up/Down counter (CTUD)

-

Range: 0–9999 or higher depending on digits

-

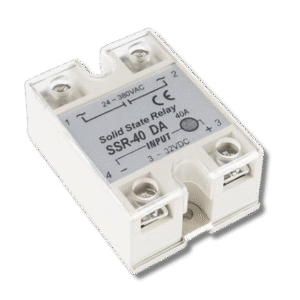

Output Contact: Relay/SSR output

-

Power Supply: 24 VDC / 110–230 VAC

-

PLC Interface: Digital input/output or Modbus (in advanced models)

Key Features

✅ High-speed counting capability

✅ Multiple counting modes (Up, Down, Up/Down)

✅ PLC compatibility with sensor inputs (proximity, photoelectric, encoder)

✅ Preset values for batch/production control

✅ Compact panel-mounted digital counters available

✅ Reset, preset, and hold functions

Applications

Production Counting (number of items produced, packaged)

-

Conveyor Systems (object detection and counting)

-

Batch Control (dispensing and filling applications)

-

Rotational Speed & Length Measurement (encoders in motors, rollers)

-

Machine Cycles (number of strokes, operations, or runs)

-

Quality Control (reject count, defect tracking)

Advantages

✔ Accurate event/object counting

✔ Can be implemented in hardware or PLC software

✔ Reduces manual tracking & errors

✔ Easy integration with PLC and SCADA systems

✔ Useful for both discrete & continuous process monitoring

Disadvantages

✖ Hardware counters add extra cost compared to PLC logic

✖ Sensor or wiring failure may affect counting accuracy

✖ High-speed counting may require special PLC modules

✖ Requires calibration and testing for precise applications