A flow sensor detects and monitors the flow of fluid, converting it into an electrical signal that can be read by a control system or display unit. Different technologies are used, such as turbine, ultrasonic, electromagnetic, and thermal flow sensors.

Description

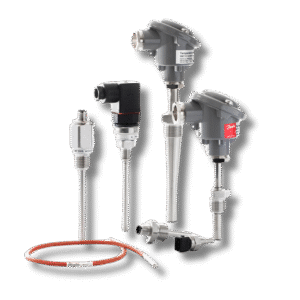

A Flow Sensor is an essential measuring device used to detect and monitor the rate or volume of liquids and gases moving through a system. It converts the flow into an electrical signal, enabling accurate monitoring, control, and automation of industrial, commercial, and medical processes. Available in various technologies such as turbine, ultrasonic, electromagnetic, and thermal, flow sensors are widely used in industries like water treatment, oil & gas, HVAC, food processing, and healthcare to ensure efficiency, safety, and resource optimization.

Types of Flow Sensors

-

Turbine Flow Sensor – Uses a rotating turbine inside the flow path.

-

Electromagnetic Flow Sensor – Works on Faraday’s Law of Electromagnetic Induction.

-

Ultrasonic Flow Sensor – Uses sound waves to measure velocity of fluid.

-

Thermal Mass Flow Sensor – Measures heat dissipation in a flowing medium.

-

Differential Pressure Flow Sensor – Uses pressure drop across an obstruction (like an orifice plate).

Specifications (common parameters)

-

Flow range (e.g., 0.1 to 200 L/min)

-

Accuracy (±0.5% to ±2% of reading)

-

Output type (Analog 4–20mA, Digital pulse, RS485, etc.)

-

Fluid compatibility (water, oil, chemicals, air, gas)

-

Operating temperature and pressure

Features

-

Real-time monitoring of flow.

-

High accuracy and repeatability.

-

Wide range of fluid compatibility.

-

Can provide both flow rate and total flow measurement.

-

Available in compact or industrial-grade designs.

Applications

-

Water treatment plants

-

Chemical processing

-

Oil & gas industries

-

Food & beverage industry

-

Medical devices (IV flow monitoring, ventilators)

-

HVAC (Heating, Ventilation, Air Conditioning)

-

Automotive fuel monitoring

Advantages

-

Accurate and reliable measurement

-

Improves process control and efficiency

-

Reduces wastage of resources

-

Supports automation and remote monitoring

Disadvantages

-

Some types (like turbine sensors) require regular maintenance

-

Accuracy may be affected by fluid properties (temperature, viscosity, bubbles)

-

High cost for advanced types (ultrasonic, electromagnetic)

-

Installation may require cutting into pipelines