A humidity controller and sensor integrated with a PLC enables accurate monitoring and automatic regulation of moisture levels in industrial and commercial environments. Widely used in HVAC, food storage, pharmaceuticals, agriculture, and clean rooms, it ensures product quality, process efficiency, and reliable environmental control.

Description

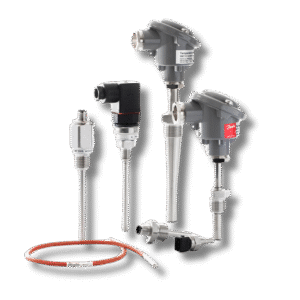

A humidity sensor (also called a hygrometer) measures the amount of moisture in the air, while a humidity controller regulates and maintains the desired humidity level in industrial or commercial environments. When integrated with a PLC, they provide automated monitoring and control of humidity for critical processes in industries like food storage, pharmaceuticals, HVAC, agriculture, and clean rooms.

Specifications

-

Sensor Types: Capacitive, Resistive, Thermal conductivity-based

-

Measuring Range: 0% RH to 100% RH

-

Accuracy: ±2% RH to ±5% RH (depending on model)

-

Output Signal: 0–10 V / 4–20 mA / Digital (Modbus, RS485, etc.)

-

Controller Type: On/Off or PID-based humidity control

-

Interface with PLC: Analog input modules or communication modules

-

Operating Temperature Range: -20°C to +80°C (varies with design)

-

Applications: Indoor/outdoor, industrial, commercial, and agricultural use

Key Features

✅ High-accuracy humidity sensing

✅ Integrated temperature & humidity measurement (in many models)

✅ PLC-compatible analog/digital outputs

✅ On/Off or PID control for humidifiers/dehumidifiers

✅ Durable design for industrial environments

✅ Fast response time for real-time control

✅ Wide application in automation systems

Applications

-

Food & Beverage Industry (storage, drying, fermentation)

-

Pharmaceuticals & Clean Rooms (precise environmental control)

-

HVAC Systems (air conditioning, comfort control)

-

Agriculture & Greenhouses (crop growth optimization)

-

Textile Industry (moisture control in yarn and fabric)

-

Warehouses & Cold Storage (spoilage prevention)

Advantages

✔ Accurate humidity control for sensitive processes

✔ Enhances product quality and shelf life

✔ Easy integration with PLCs and SCADA systems

✔ Reduces human intervention in monitoring

✔ Supports energy-efficient environmental control

Disadvantages

✖ May require calibration for long-term accuracy

✖ Sensor performance can degrade in harsh/contaminated environments

✖ Higher precision models are more expensive

✖ Limited lifespan in highly humid or corrosive areas