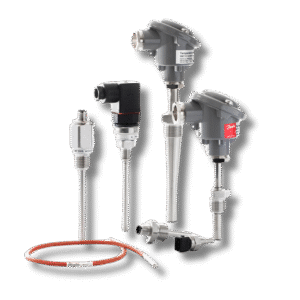

Limit switches are electromechanical position sensing devices that detect the presence, movement, or end position of an object using a mechanical actuator. When the actuator is engaged, it triggers internal contacts to open or close, enabling precise control in automation and safety systems. Known for their rugged construction, repeatability, and long service life, limit switches are widely used in industrial machines, conveyor systems, elevators, packaging equipment, and safety interlocks. They remain one of the most reliable and cost-effective solutions for position detection in harsh industrial environments.

Description

A Limit Switch is an electromechanical device used to detect the presence, absence, or position of a moving object. It operates through a mechanical actuator that triggers electrical contacts when an object reaches a set point, making it widely used in automation, safety, and position sensing applications.

Specifications

-

Actuator Types: Plunger, Roller Lever, Rod Lever, Adjustable Lever

-

Contact Types: NO, NC, SPDT, DPDT

-

Operating Voltage: 24V DC, 110V AC, 230V AC

-

Current Rating: 5A – 15A

-

Mechanical Life: Up to 10 million operations

-

Standards: IEC 60947-5-1, EN 60947

Features

-

Rugged construction for industrial environments

-

High repeatability and precision

-

Wide variety of actuator designs

-

Supports direct load switching

-

Long mechanical & electrical life

-

Compact and easy to mount

Applications

-

Industrial automation – detecting machine part positions

-

Conveyor systems – object counting & detection

-

Elevators & cranes – travel limit control

-

Packaging machines – end-of-travel detection

-

Safety interlocks – ensuring doors or panels remain closed

Advantages

-

Simple and reliable design

-

High durability with millions of cycles

-

Accurate and repeatable switching

-

Suitable for harsh environments

Disadvantages

-

Requires physical contact to operate

-

Can wear out mechanically over time

-

Not suitable for non-contact sensing (use proximity sensors instead)