Power Quality Analysers are advanced instruments designed to measure, monitor, and analyze electrical parameters in power systems. They help identify issues like harmonics, voltage sags, swells, flicker, and transients that affect equipment performance and efficiency. Widely used in industries, utilities, and energy audits, these devices ensure reliable power quality, system compliance, and reduced downtime through accurate real-time monitoring and data logging.

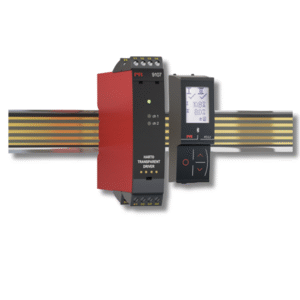

Description

Power Quality Analysers are advanced measuring instruments used to monitor, record, and analyze electrical parameters in power systems. They detect disturbances such as harmonics, voltage sags, swells, flicker, transients, and unbalances that can affect the efficiency and reliability of electrical equipment. Widely used in industries, utilities, and commercial facilities, these devices help maintain compliance with power standards, improve system efficiency, and prevent costly downtime.

Specifications

-

Measurement Parameters: Voltage, Current, Frequency, Power Factor, Harmonics, THD, Flicker, Transients

-

Voltage Range: Up to 1000V AC (model dependent)

-

Current Range: Via CTs (up to several kA)

-

Accuracy: Class 0.2s / 0.5s (IEC standards)

-

Display: LCD / TFT touch screen with graphical interface

-

Data Logging: Built-in memory or SD card support

-

Communication: RS485 (Modbus RTU), Ethernet, Wi-Fi, USB, GSM/4G

-

Mounting: Portable / Panel mount / DIN rail models

-

Compliance: IEC 61000-4-30 Class A, IEC 61000-4-7, IEC 61000-4-15

Applications

-

Power utilities and substations

-

Industrial plants and factories

-

Commercial buildings and data centers

-

Renewable energy systems (solar, wind)

-

Energy audits and load studies

-

Preventive maintenance and fault diagnosis

Advantages

-

Detects and records all major power disturbances

-

Improves system reliability and energy efficiency

-

Helps in compliance with international power quality standards

-

Supports real-time monitoring and remote data access

-

Reduces downtime and maintenance costs by early fault detection

Disadvantages

-

High-end models can be expensive

-

Requires skilled personnel for setup and data interpretation

-

Sensitive instruments may need regular calibration