An SCR Power Regulator controls the voltage and current supplied to electrical loads, ensuring precise power management in industrial applications. Integrated with PLCs, it is widely used in heaters, furnaces, plastics, chemical, and HVAC systems, offering energy efficiency, accuracy, and reliable automation.

Description

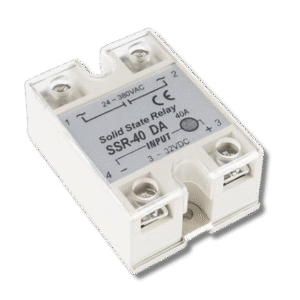

An SCR (Silicon Controlled Rectifier) Power Regulator is an electronic device that controls the power delivered to electrical loads, especially resistive and inductive loads like heaters, furnaces, and motors. It works by adjusting the firing angle of SCRs to regulate the voltage, current, or power supplied to the load. In PLC-based systems, SCR power regulators are widely used for precise temperature control, energy savings, and process automation.

Specifications

-

Input Control Signal: 4–20 mA, 0–10 V, 0–5 V, or PLC digital control

-

Output Voltage Range: 24–480 VAC / up to 600 VAC (model-dependent)

-

Load Current Range: 10 A to 1000 A

-

Control Modes: Phase angle control / Zero-cross control

-

Firing Method: Burst firing, phase angle, or hybrid

-

Cooling: Natural air cooling / Forced air / Heat sink

-

Protection: Overcurrent, overvoltage, overtemperature, short-circuit protection

-

PLC Interface: Analog input module, digital control signals, Modbus (in smart models)

Key Features

✅ Smooth and precise power regulation

✅ Multiple control modes (phase angle, zero-cross, burst firing)

✅ PLC-compatible analog & digital inputs

✅ Compact and rugged design for industrial use

✅ Built-in protection for safe operation

✅ Energy-efficient and reduces electrical stress on loads

✅ Suitable for resistive, inductive, and transformer loads

Applications

Industrial Heaters & Furnaces (temperature regulation)

-

Plastic Extrusion & Injection Molding (heater bands, hot runners)

-

Chemical & Pharma Processing (reactors, dryers)

-

Glass & Ceramic Industries (kilns, melting furnaces)

-

HVAC Systems (electric heaters, ducts)

-

Lighting Control (dimming high-power lamps)

Advantages

✔ High precision control over power delivery

✔ Reduces power fluctuations and energy wastage

✔ Long lifespan due to solid-state switching

✔ Compatible with PLC automation for closed-loop control

✔ Improves product quality with stable heating

Disadvantages

✖ Generates heat, requiring proper cooling

✖ More expensive than traditional contactor-based control

✖ Sensitive to electrical surges & harmonics

✖ Requires skilled setup & tuning

✖ May produce electrical noise in phase angle control