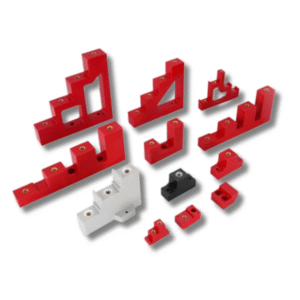

Stud Type Terminal Blocks are heavy-duty connectors designed for secure termination of large cross-section wires and cables. Using a stud-and-nut assembly, they provide strong, vibration-resistant connections capable of handling high currents. Ideal for power distribution panels, switchgear, generators, and industrial machinery, these terminal blocks ensure safe, durable, and reliable performance in demanding electrical applications.

Description

Stud Type Terminal Blocks are heavy-duty connectors designed for secure termination of large cross-section wires and cables. Instead of clamps or spring mechanisms, they use threaded studs with nuts and washers to firmly hold conductors in place, ensuring high mechanical strength and excellent electrical conductivity. These terminal blocks are ideal for power distribution in demanding industrial, commercial, and utility applications.

Specifications

-

Type: Stud / Screw-Type Terminal Block

-

Stud Size: M4, M5, M6, M8, M10, M12 (varies by model)

-

Rated Voltage: Up to 1000V AC/DC

-

Rated Current: 60A – 500A (depending on size)

-

Conductor Size: Suitable for large cross-section cables (up to 300 mm²)

-

Mounting: DIN rail or panel mounting

-

Material: High-strength flame-retardant insulation body (PA, DMC, or Bakelite)

-

Connection: Stud & nut tightening with flat/spring washers for secure grip

-

Standards Compliance: IEC / UL certified

Applications

-

Power distribution systems

-

Electrical panels and switchgear

-

Transformer and generator connections

-

Industrial machinery and heavy equipment

-

Railway, marine, and renewable energy systems

-

Utility substations and high-current circuits

Advantages

-

Handles high current and large conductor sizes

-

Strong, vibration-resistant connections using stud and nut assembly

-

Simple and durable design with long service life

-

Suitable for harsh industrial environments

-

Easy to connect multiple conductors with lugs

Disadvantages

-

Requires cable lugs for termination

-

Bulkier than standard terminal blocks

-

Installation takes longer compared to spring-clamp types