A Timer is used in automation to control operations based on time intervals, available as hardware modules or PLC software timers. Widely applied in motor control, sequence automation, conveyors, and safety interlocks, timers ensure precise, reliable, and flexible process control in industrial systems.

Description

A Timer is a control device used in automation to measure time intervals and control operations accordingly. In PLC systems, timers are available as software functions (TON, TOF, TP) as well as external hardware timers used in control panels. They are widely applied in sequence control, delay operations, motor control, process cycles, and safety interlocks.

Specifications

-

Timer Modes: ON-delay, OFF-delay, Interval, Cyclic (Repeat cycle)

-

Time Range: Milliseconds to hours (model-dependent)

-

Display: Digital/Analog scale (for standalone timers)

-

Input Signal: 24 VDC / 110–230 VAC (PLC or field input)

-

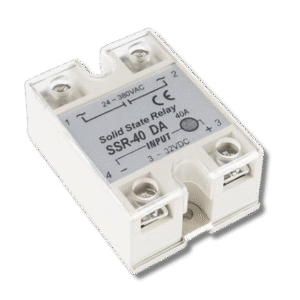

Output Contact: Relay/SPDT/SSR output

-

Accuracy: ±0.1% to ±1%

-

Mounting: Panel mount / DIN rail

-

PLC Interface: Digital I/O module

Key Features

✅ Multiple timing modes (On-delay, Off-delay, Pulse, Cyclic)

✅ High accuracy and repeatability

✅ PLC-compatible digital input/output

✅ Available in hardware or software form (ladder logic timers)

✅ Compact, durable design for industrial environments

✅ Easy configuration and monitoring

Applications

-

Sequential Machine Control (start/stop delays)

-

Motor Control (star-delta starter timing, overload delays)

-

Process Automation (batching, mixing, heating cycles)

-

Lighting Control (delayed ON/OFF operations)

-

Conveyor Systems (interval-based movement)

-

Safety & Interlocks (delay-before-start mechanisms)

Advantages

✔ Simplifies sequence and process control

✔ High timing precision

✔ Flexible time ranges for multiple applications

✔ Reduces manual intervention

✔ Integrates easily with PLC programs

Disadvantages

✖ External timers add cost compared to PLC software timers

✖ Hardware timers need wiring & panel space

✖ Failure of a timer can halt process operations

✖ Limited functions in low-cost models compared to PLC logic