A Voltage & Current Meter measures and displays electrical parameters like voltage, current, and power, ensuring accurate monitoring, energy management, and PLC integration for safe and efficient industrial automation.

Description

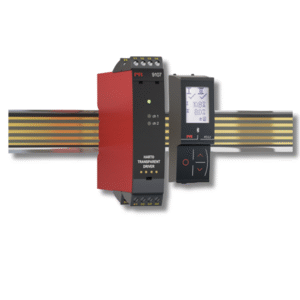

A Voltage & Current Meter is an electrical measuring device used to monitor and display voltage, current, and sometimes power parameters in industrial and automation systems. These meters help in process monitoring, energy management, fault detection, and PLC integration to ensure reliable and efficient plant operation.

Specifications

Input Voltage Range: 0–500V AC/DC (model-dependent)

-

Input Current Range: 0–200A AC/DC (with CT/PT support)

-

Display: Digital LED/LCD, multi-parameter display

-

Accuracy: ±0.5% to ±1%

-

Output Signal: 4–20 mA / RS485 Modbus / Digital output

-

Mounting: Panel mount / DIN rail

-

Power Supply: 24 VDC / 110–230 VAC

-

PLC Interface: Analog or Modbus communication

Key Features

✅ Measures voltage, current, and power parameters

✅ Digital/LED display for real-time monitoring

✅ Supports analog and Modbus outputs for PLC integration

✅ High accuracy and fast response

✅ Compact panel-mounted design

✅ Alarm/trip relay output in advanced models

Applications

Energy Management Systems (monitoring power usage)

-

Motor & Machine Monitoring (current load, overvoltage protection)

-

Process Industries (voltage/current feedback to PLCs)

-

Power Distribution Panels (substations, control panels)

-

Testing & Calibration (laboratories, R&D setups)

-

Industrial Automation (protection and optimization of loads)

Advantages

✔ Real-time monitoring of electrical parameters

✔ Prevents equipment damage due to overloads/faults

✔ Enhances energy efficiency and cost savings

✔ Easy integration with PLC & SCADA systems

✔ Available in single-phase and three-phase models

Disadvantages

✖ Needs proper CT/PT selection for accuracy

✖ High-end models are costly

✖ Requires calibration & periodic maintenance

✖ Limited features in low-cost versions