-

Consulting & Product Selections

-

Control Panels Designing

-

Manufacturing

-

Wiring & Harness

-

Troubleshooting

-

Programming

Consulting & Product Selection

At Mine Power, we understand that choosing the right electrical components and systems is critical to the success and efficiency of your project. Our Product Selection & Consulting service ensures that you get tailored solutions that meet your technical, operational, and budgetary requirements. Here’s how we do it:

We begin by listening to your project goals, site conditions, and specific requirements—whether it's for an industrial plant, commercial building, or automation system.

Our team can conduct an on-site evaluation to better understand your existing setup, load demands, and future scalability needs.

Based on your inputs and assessment, we analyze load calculations, environmental factors, energy usage patterns, and compliance standards.

Using our expertise and strong industry partnerships, we recommend the best-fit products—be it electrical panels, protection devices, control systems, or automation components—from trusted manufacturers.

We provide a detailed list of suggested products with specifications, benefits, and why they’re right for your project—focusing on energy efficiency, safety, performance, and cost-effectiveness.

We walk you through our recommendations, address your queries, and fine-tune the solution based on your feedback.

You’ll receive full technical documentation and ongoing support for installation, integration, and future upgrades.

Designing & Building Electrical Panels

At Mine Power, we specialize in designing and manufacturing high-quality electrical panels tailored to your unique industrial or commercial requirements. Our end-to-end process ensures safety, reliability, and performance in every panel we deliver.

We start by understanding your specific application needs, including load requirements, type of equipment, safety regulations, environmental conditions, and any customization preferences.

If necessary, we perform a detailed site inspection and review your existing electrical systems to ensure compatibility, space planning, and future scalability.

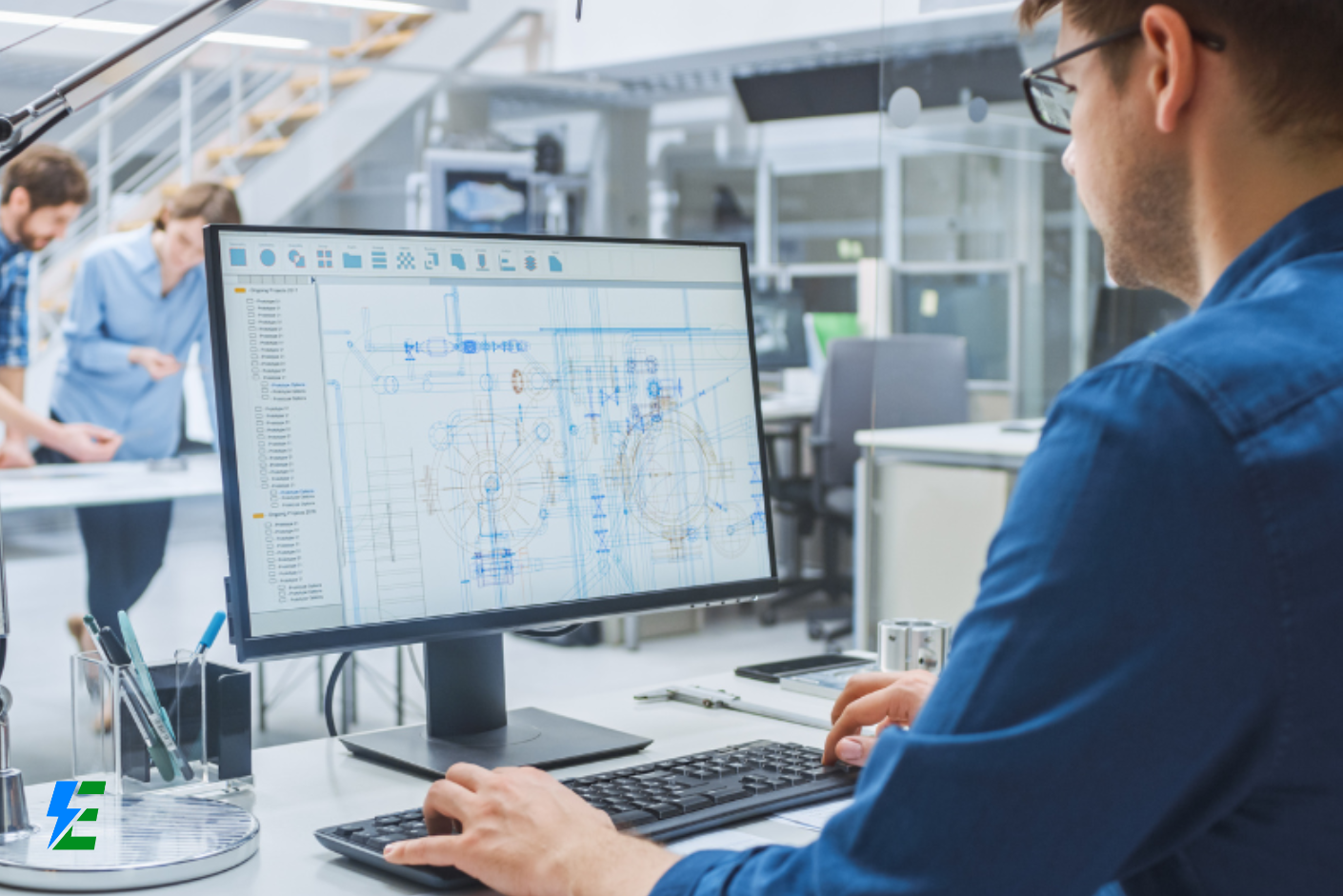

Using advanced CAD tools and electrical design software, our engineering team creates detailed panel layouts, wiring diagrams, and component placements. We ensure:

- Compliance with IEC/IS standards

- Optimal layout for cooling and service access

- Clear labeling and documentation for ease of maintenance

We source only high-quality components from trusted brands (e.g., Schneider, Siemens, ABB, etc.), selecting based on performance, durability, and your specific technical needs.

In our facility, skilled technicians fabricate the panel enclosure, mount components, and carry out precise wiring and assembly. We follow strict quality control and safety practices throughout this phase.

Each panel undergoes rigorous testing, including:

- Continuity and insulation resistance

- Functional checks

- Load simulations (if required)

- Safety and compliance verification

- We ensure the panel is ready for trouble-free installation and operation.

Panels are carefully packaged and delivered to your site. If needed, we provide on-site installation guidance or coordination with your technical team.

We provide complete documentation, including:

- Wiring diagrams

- Load calculations

- Test reports

- Operating instructions

- Maintenance guidelines

Our job doesn’t end at delivery. We offer after-sales technical support, troubleshooting assistance, and guidance for future expansion or upgrades.

Electrical Panel Manufacturing

We begin by gathering detailed information from the client, including:

- Electrical load requirements

- Application type (industrial, commercial, automation, etc.)

- Control and protection needs

- Panel type (PCC, MCC, APFC, VFD, PLC, etc.)

- Our engineers review the data to define technical specifications that guide the entire manufacturing process.

Using professional design software (like AutoCAD, EPLAN), our team develops:

- General arrangement (GA) drawings

- Single-line diagrams (SLDs)

- Wiring and terminal layouts

- Bill of materials (BOM)

- We ensure every design complies with IEC/IS standards and is optimized for functionality, maintenance, and space utilization.

We source high-quality electrical components from trusted brands such as:

- Schneider Electric

- Siemens

- ABB

- L&T

- Omron and others

- All materials are verified against specifications before entering production.

Based on design requirements, we fabricate the panel enclosure using high-grade sheet metal or stainless steel. The process includes:

- Cutting, bending, and welding

- Surface treatment and powder coating

- Drilling and mounting provisions

- The result is a durable, corrosion-resistant, and well-finished cabinet ready for assembly.

Our skilled technicians assemble the components inside the enclosure, following approved drawings. This includes:

- Mounting switchgear, meters, relays, terminals, and busbars

- Internal and external wiring using standard color codes and ferrules

- Labeling for easy identification and maintenance

- Proper cable routing and spacing are maintained to avoid overheating and ensure safety.

Each panel undergoes thorough testing as per standards. Tests include:

- Visual inspection and checklist validation

- Continuity and insulation resistance tests

- Functional testing of protection devices and interlocks

- Load simulation tests (if required)

- We ensure the panel meets performance, safety, and quality benchmarks before dispatch.

The final panel is cleaned, sealed, and packed securely for transport. We ensure proper protection during shipping to prevent damage.

We provide comprehensive documentation with every panel, including:

- Wiring diagrams and GA drawings

- Test certificates

- Operation and maintenance manuals

- Component datasheets

We offer installation guidance or on-site support as needed. Our team is always ready to assist with commissioning, troubleshooting, and future upgrades.

- Why Choose Mine Power for Panel Manufacturing?

Precision engineering and robust construction - Use of top-quality branded components

- Compliance with national and international standards

- Timely delivery and excellent after-sales service

Wiring & Harness

At Mine Power, we deliver precise, well-organized wiring and harness solutions that ensure optimal connectivity, reliability, and safety in electrical systems. Our structured process guarantees consistent quality for industrial panels, automation systems, and control units.

We begin by understanding the specific requirements of the project:

- Type of panel or system (PCC, MCC, PLC, VFD, etc.)

- Voltage, current, and control signal specifications

- Environmental factors (e.g., heat, moisture, vibrations)

- Custom connector types, wire gauges, and routing needs

Using CAD software, we design detailed wiring diagrams and harness layouts, including:

- Routing paths

- Cable lengths and color codes

- Termination and connector points

- Labels and numbering for identification

- This ensures consistency, reduces errors, and improves future maintenance.

Based on the design:

- Wires are cut to precise lengths

- Stripping, crimping, and termination are performed

- Ferrules, lugs, heat-shrink sleeves, and labels are applied

- Bundles are arranged with proper spacing and insulation

- We use high-quality wires and connectors from trusted brands, ensuring durability and performance.

The prepared wires are bundled, tied, and routed based on the approved layout:

- Signal, power, and ground wires are separated to avoid interference

- Cables are secured using cable ties, clips, and ducts

- Wire numbering and color codes are followed strictly

- Flexible routing allows for easy servicing and modifications

The assembled harness is installed inside the electrical panel or system. Our technicians:

- Connect all terminals, relays, meters, contactors, and PLCs

- Ensure tight and secure terminations

- Route wires cleanly to maintain airflow and reduce clutter

- Neat and professional wiring improves heat dissipation, aesthetics, and safety.

Before handover, the wiring and harness undergo:

- Continuity checks

- Insulation resistance testing

- Verification against wiring diagrams

- Functional testing to ensure full system operation

- Every connection is inspected for accuracy, durability, and reliability.

We provide complete wiring documentation, including:

- Wiring diagrams

- Harness layout drawings

- Label reference charts

- Maintenance and service notes

- This helps technicians quickly understand and troubleshoot the system later.

Control Panel Troubleshooting

At Mine Power, we provide expert troubleshooting services for electrical control panels to ensure your systems run safely, efficiently, and without interruptions. Our systematic approach helps identify issues quickly and restore operations with minimal downtime.

The process begins when a client reports a fault or irregularity. We gather key information such as:

- Type of control panel (MCC, PLC, VFD, etc.)

- Symptoms of the issue (e.g., tripping, no output, overheating)

- Recent changes or activities on the system

- Error codes or alarms, if available

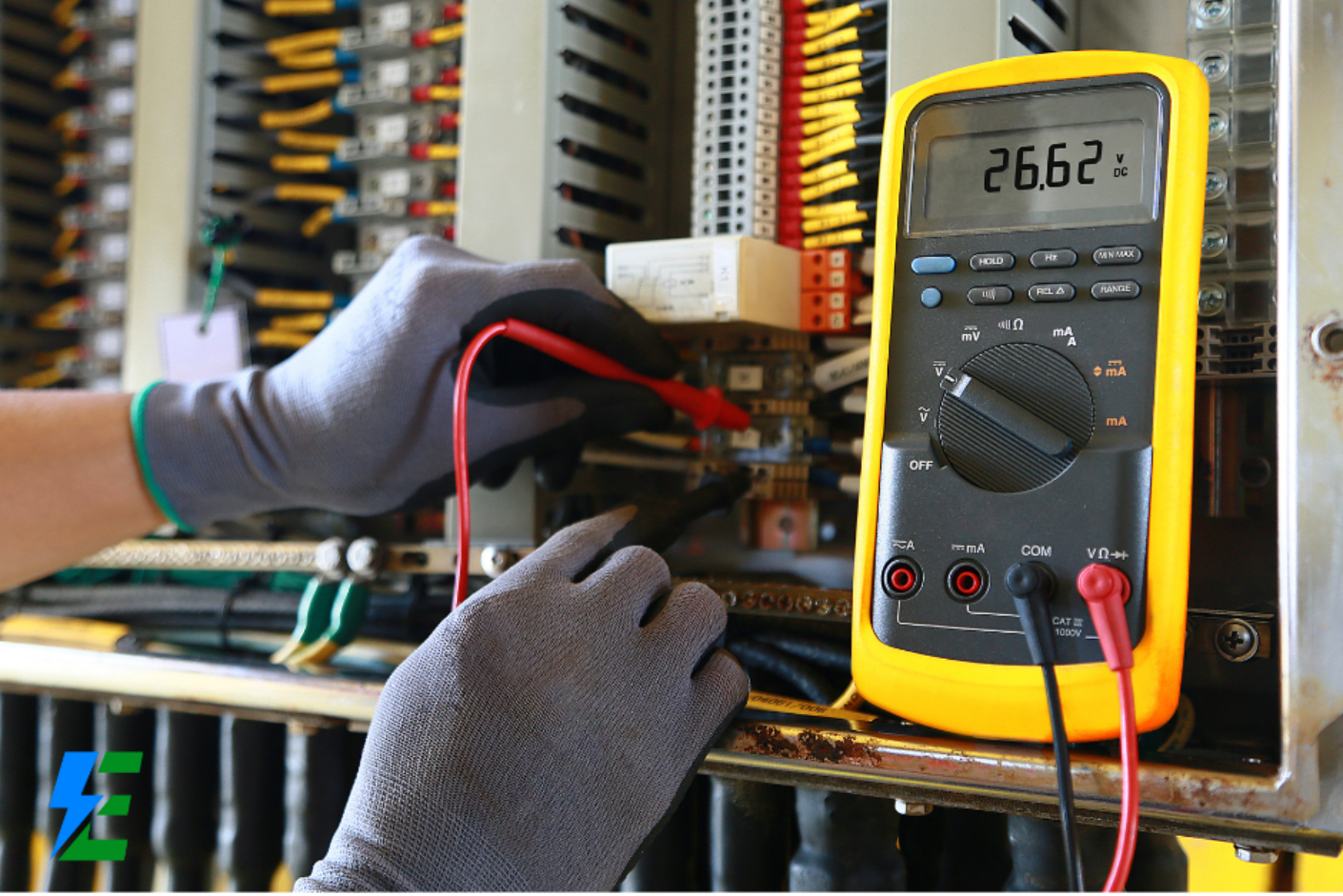

Before inspection, we ensure the system is safely isolated from the power supply. This includes:

- Lockout/Tagout procedures

- Verifying voltage absence using proper testing tools

- Ensuring safe working conditions for the technician

We begin with a thorough visual inspection to check for:

- Burn marks, loose wires, or damaged components

- Signs of corrosion, overheating, or mechanical wear

- Wire routing and panel cleanliness

- Proper labeling and terminal connections

We use calibrated tools and instruments (multimeters, thermal cameras, insulation testers, etc.) to:

- Test voltage levels, current flow, and continuity

- Check relays, contactors, timers, fuses, and breakers

- Inspect PLCs, VFDs, SMPS, and automation devices for faults

- Review logic sequence and program status (for programmable systems)

Once data is collected, we analyze the findings to determine the exact cause of the malfunction. This may involve:

- Faulty components (relays, breakers, timers)

- Wiring issues (loose, broken, or reversed wires)

- Overloads, short circuits, or ground faults

- Program or configuration errors in automation panels

After identifying the fault:

- Damaged parts are repaired or replaced

- Wires and terminals are reconnected securely

- Logic or PLC programming is corrected if needed

- Safety components (fuses, MCBs, ELCBs) are verified or replaced

We conduct a full operational test to ensure the panel is functioning correctly:

- Power-on checks

- Load testing (if required)

- Monitoring startup sequence and interlocks

- Confirming no abnormal heating, noise, or vibration

We provide a detailed report covering:

- Fault description and root cause

- Actions taken to resolve the issue

- Replacement parts and any modifications

- Suggestions for future prevention

We guide the client’s maintenance team on:

- Recognizing early warning signs

- Basic safety checks and reset procedures

- Scheduling periodic maintenance

- We also offer remote or on-site follow-up support if needed.

Electrical & Electronics Equipment Programming

At Mine Power, we specialize in programming electrical and electronic equipment to enable intelligent control, automation, and seamless integration across industrial and commercial systems. Whether it’s PLCs, HMIs, VFDs, or embedded controllers, our step-by-step approach ensures reliable performance and tailored functionality.

We begin by understanding your specific system and operational needs:

- Type of equipment (PLC, HMI, VFD, microcontroller, etc.)

- Desired automation or control functions

- Input/output requirements

- Communication protocols (Modbus, Ethernet, Profibus, etc.)

- Safety, timing, and sequencing conditions

Based on the requirements, our team develops a functional control strategy, including:

- Flow diagrams or logic charts

- Sequence of operations

- Interlock conditions

- Alarm/notification logic

- User interface (HMI/SCADA) screen layouts

- This planning ensures clarity, minimizes logic errors, and aligns with your process goals.

We configure the hardware elements of the system:

- Assign I/O addresses and memory mapping

- Configure communication interfaces and protocols

- Select appropriate expansion modules, power supplies, and sensors

- Integrate with other devices like relays, contactors, and actuators

Using industry-standard software (e.g., Siemens TIA Portal, Allen-Bradley RSLogix, Schneider EcoStruxure, Arduino IDE), we:

- Write control logic (Ladder Logic, Structured Text, Function Block, etc.)

- Program automation routines for timing, feedback, and control loops

- Develop intuitive HMI/SCADA interfaces for user interaction

- Configure VFDs or servo drives with proper parameters

Before deploying, we test the logic offline to:

- Simulate real-world scenarios and machine behavior

- Detect programming errors or conflicts

- Ensure sequences, alarms, and interlocks work as intended

- This reduces commissioning time and improves safety during real-time deployment.

Once programming is complete:

- We upload the logic/program into the actual equipment

- Verify I/O signals, connections, and feedback devices

- Test the entire system under live conditions

- Fine-tune parameters, speeds, and response times as needed

- Ensure safe and stable operation

We train your team on:

- Operating the system via HMI/SCADA

- Responding to alarms and alerts

- Basic troubleshooting and resets

- Backing up and restoring programs

- We also provide full documentation and source code backups.

Our relationship doesn’t end after delivery. We offer:

- Remote and on-site support

- Periodic program updates

- Enhancements for expanded operations

- Troubleshooting assistance for logic or system faults

Mine Power is a leading Electrical automation solutions provider, serving diverse industries with a skilled team of engineers boasting over 10 years of experience.