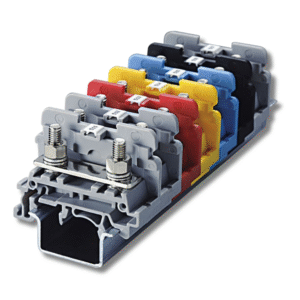

The Bus Bar Support is a high-strength insulating component designed to firmly hold and secure bus bars in electrical panels, switchgear, bus ducts, and substations. Manufactured from premium DMC/SMC/Epoxy materials, it provides excellent mechanical strength, thermal stability, and electrical insulation to ensure safe and reliable power distribution.

Available in various sizes and designs (cylindrical, hexagonal, pedestal types), these supports can withstand high fault currents and elevated temperatures. They are widely used in low voltage and medium voltage applications, ensuring long-term durability and maintenance-free operation.

Description

A bus bar support (also called a bus bar insulator or bus bar holder) is usually made of high-strength insulating materials like DMC (Dough Moulding Compound), SMC (Sheet Moulding Compound), epoxy resin, or polyamide. It is mounted inside electrical enclosures to hold the bus bar firmly in position, preventing mechanical stress, vibrations, and electrical faults.

Features

-

High mechanical strength to withstand heavy bus bar loads.

-

Excellent electrical insulation to prevent short circuits.

-

High thermal resistance to withstand temperature rise due to current flow.

-

Available in different shapes (cylindrical, hexagonal, pedestal types).

-

Easy mounting with screws, bolts, or studs.

Specifications

-

Material: DMC/SMC/Epoxy/Polyamide.

-

Voltage rating: 1 kV to 36 kV (depending on application).

-

Withstand current: Up to 5000 A or more.

-

Flame resistance: UL94 V-0 (for high-quality supports).

-

Sizes: Vary depending on bus bar width & thickness (e.g., 12 mm – 100 mm bus bars).

Advantages

✅ Provides strong insulation and prevents phase-to-phase faults.

✅ Increases system safety and reliability.

✅ Reduces mechanical stress on bus bars during fault currents.

✅ Long life, maintenance-free, and resistant to heat, moisture, and corrosion.

Disadvantages

❌ Adds to system cost.

❌ Requires proper alignment during installation.

❌ Limited reusability if damaged.

Applications

-

Electrical panels and switchgear.

-

Power distribution boards.

-

Bus ducts and bus bar chambers.

-

Substations and industrial control panels.

-

UPS & renewable energy distribution systems.