Microcontroller vs PLC: Which One Powers the Future of Automation?

If you’ve ever wondered why your washing machine runs smoothly at home but factories rely on huge control panels to operate thousands of machines, the answer lies in two silent heroes of automation: the Microcontroller (MCU) and the Programmable Logic Controller (PLC).

At first glance, both seem to do the same job—control machines and processes—but in reality, they live in two different worlds. One thrives in your gadgets, the other rules the factory floor. Let’s dive into the differences in a way that’s simple, clear, and maybe even a little fun.

What is a Microcontroller?

Think of a microcontroller as the brain inside small everyday devices. It’s tiny, cost-effective, and packed with everything it needs—processor, memory, and input/output pins—all on a single chip.

Everyday examples:

-

The beep when your microwave finishes cooking

-

A toy robot following a line on the floor

-

Smartwatches tracking your heart rate

In short: If it fits in your pocket or home, chances are a microcontroller is inside.

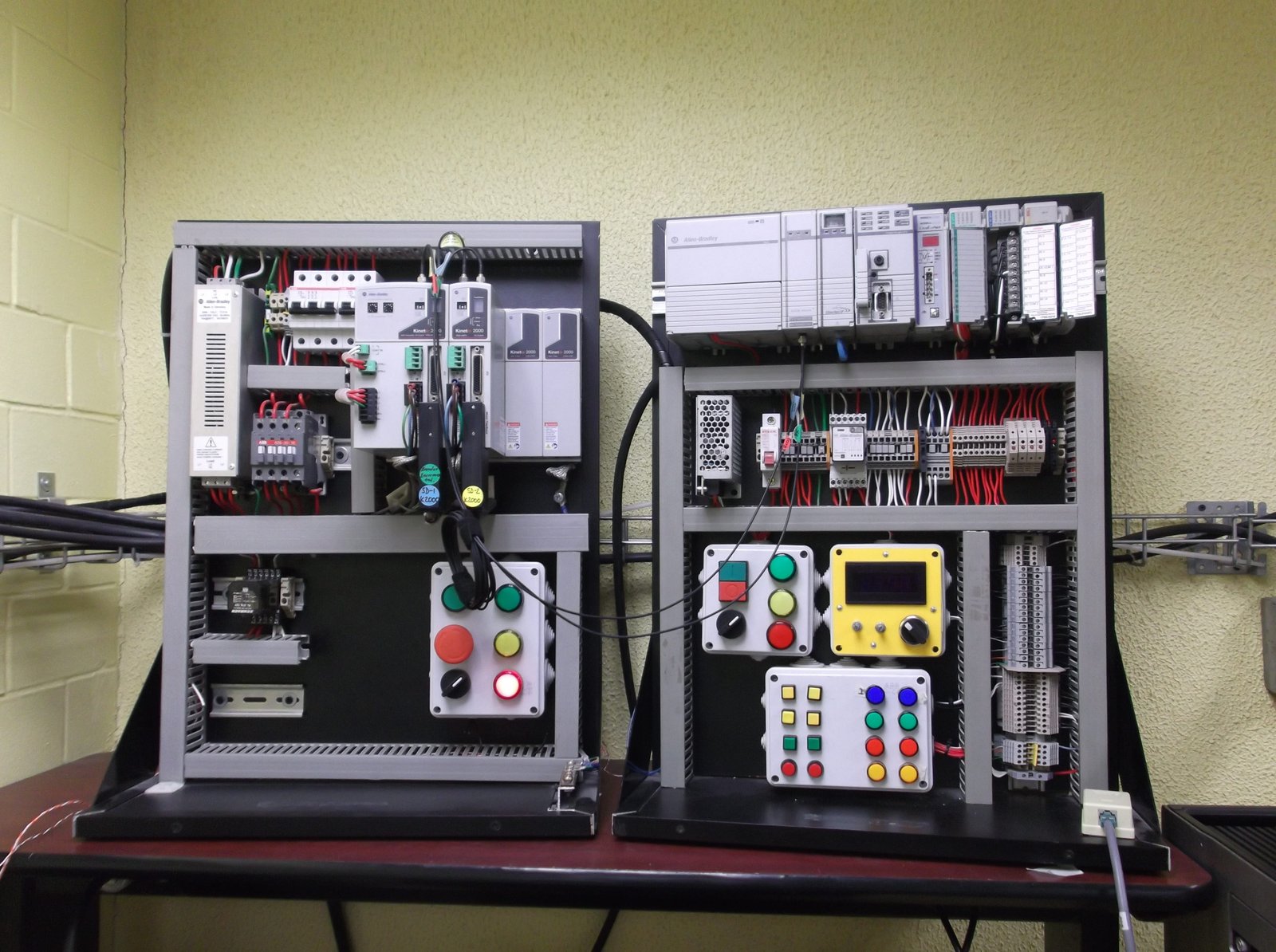

What is a PLC?

On the other hand, a PLC is like the rugged workhorse of the automation world. Born in factories, it’s designed to survive dust, heat, electrical noise, and even the occasional bump or vibration. Unlike microcontrollers, PLCs are modular and scalable—perfect for handling hundreds (or thousands) of inputs and outputs.Industrial examples:

-

Assembly lines in car manufacturing

-

Conveyor belts in packaging plants

-

Oil refineries and power stations

In short: If it runs 24/7 in a tough environment, a PLC is the boss.

Key Differences: Microcontroller vs PLC

|

Feature |

Microcontroller (MCU) | PLC (Programmable Logic Controller) |

|---|---|---|

| Design Purpose | Small devices, embedded systems | Industrial automation & heavy-duty control |

| Programming | C, C++, Assembly (needs coding skills) | Ladder Logic, Function Block (easy for engineers) |

| Durability | Not rugged—needs extra protection | Industrial-grade, built to last in harsh conditions |

| Cost | Very low ($1–$20) | High ($300–$5000+) |

| Scalability | Limited I/O | Modular, handles thousands of I/O |

| Applications | Home appliances, robotics, consumer gadgets | Factories, chemical plants, large machines |

Which One Should You Choose?

-

Choose a Microcontroller if you’re:

-

Building a smart home gadget

-

Designing a robot

-

Working on DIY electronics

-

-

Choose a PLC if you’re:

-

Automating an industrial process

-

Controlling heavy machinery

-

Managing operations where downtime is not an option

-

Final Thoughts

Both microcontrollers and PLCs are champions in their own arenas. Microcontrollers shine in flexibility and cost-effectiveness, while PLCs dominate when it comes to reliability and scalability.

So, the next time you look at your smartwatch or pass by a massive factory assembly line, you’ll know: one is powered by the tiny genius of a microcontroller, and the other by the unstoppable muscle of a PLC.

Pros & Cons

Example:

| Feature | Microcontroller | PLC |

|---|---|---|

| Cost | Very low | High |

| Environment | Home, DIY, gadgets | Harsh, industrial |

| Learning Curve | Needs coding skills | Easier (ladder logic) |

| Reliability | Limited | Extremely high |

Real-Life Example Stories

-

MCU: “Your smartwatch monitoring your heart rate every second uses a microcontroller.”

-

PLC: “A car factory with hundreds of robotic arms depends on PLCs to keep production running 24/7.”

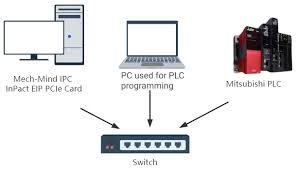

The Future of Automation: Industry 4.0

-

Microcontrollers are powering the Internet of Things (IoT)—from smart homes to wearable health tech.

-

PLCs are evolving into IIoT-ready controllers, connecting entire factories to the cloud for predictive maintenance and real-time data.

-

Together, they’re moving towards AI integration and edge computing, where decisions happen instantly at the device level.

👉 So the real answer? Both MCUs and PLCs will continue to dominate—each in their own arena.

Pro tip: If you’re an engineer, hobbyist, or someone stepping into automation, understanding both will give you the edge to choose the right tool—and maybe even innovate the next big thing.

“Are you more excited about microcontrollers shaping our gadgets, or PLCs powering smart factories? Share your thoughts below!”

Mohammed Sallick

September 12, 2025Insightful blog, got some intresting facts about both heroes in their own world. Lookin ng forward for future contents

Mohammed Sallick

September 12, 2025Insightful blog, got some intresting facts about both heroes in their own world. Lookin ng forward for future contents

Akash kumar

October 23, 2025This article provides a clear and engaging comparison between microcontrollers and PLCs, effectively highlighting their respective strengths and ideal applications. It’s an excellent resource for anyone looking to understand the future of automation technologies. https://www.gicindia.com/product-category/programmable-logic-controller/

proknigi.org

October 29, 2025Супер работа, вот буквально пару дней назад исследовал по схожему вопросу!