MCU vs PLC: Rivals or Partners in the Future of Automation?

A smartwatch is powered by one. The other powers a whole plant.

Up close, Microcontrollers (MCUs) and Programmable Logic Controllers (PLCs) exist in different worlds.

But what really matters is what is going to result when the two collaborate?

Recognizing Their Roles

Microcontrollers (MCUs): The Silent Brains of Everyday Life

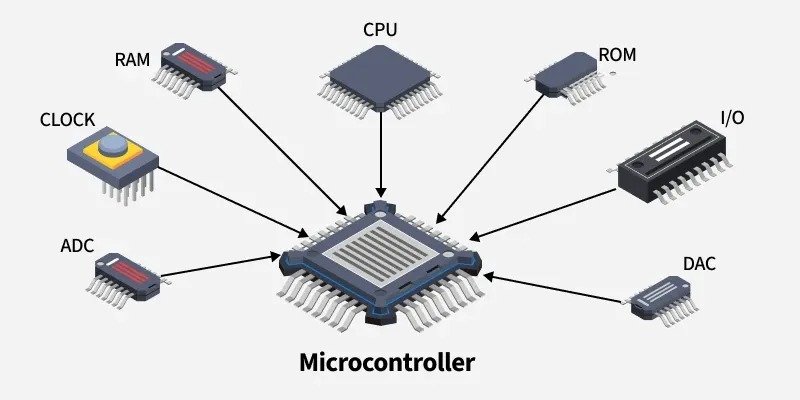

From clocks and television remote controls to Internet of Things devices, MCUs are small, out-of-sight engines powering our daily world. Small, inexpensive, and programmable, they lend themselves well to controlling sensing, signal conditioning, and limited decision-making.

Programmable Logic Controllers (PLCs):The Industrial Guardians

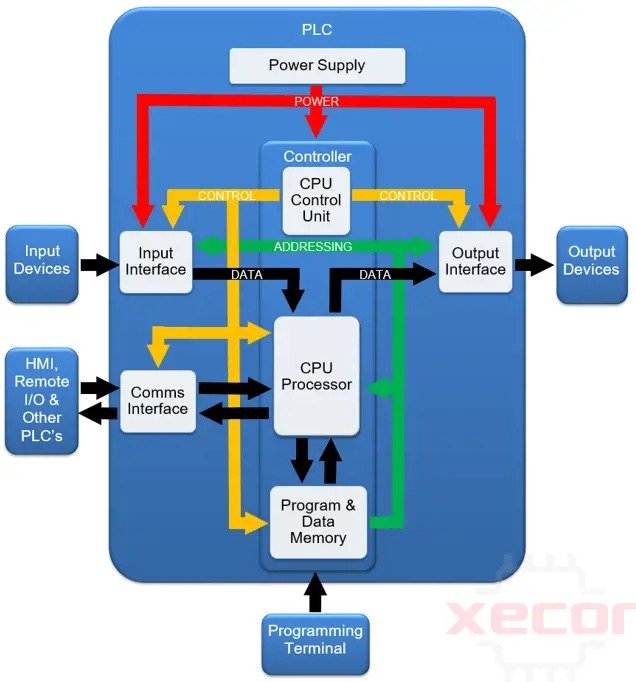

PLCs are rugged equipment packages in factories, refineries, and power stations that run machines safely and predictably. Robust and constructed to harsh environments, they have long lifespans, are modular, and are deterministic in behavior.

Why Are They Dependent on Each Other?

MCUs are masters at sensing: collecting raw data such as temperature, vibration, voltage, or pressure.

PLCs excel at decision-making: executing control logic with high reliability under strict timing.

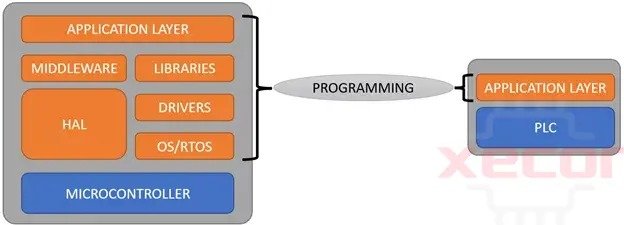

They constitute a closed automation loop in combination: MCUs are applied as “eyes and ears,” whereas PLCs are applied as “brain and hands.”

Daily Life Collaborations

Agriculture – MCUs detect soil moisture, PLCs determine time for irrigation.

Energy → MCUs monitor solar panel generation, PLCs regulate grid supply.

Industry → MCUs watch over motor health, PLCs initiate maintenance alarms.

Transportation→ MCUs sense level of traffic, PLCs regulate signals.

This isn’t rivalry. It’s teamwork.

Just a Quick Look Back

Relay logic panels, when used previously to PLCs, were enormous, expensive, and vulnerable to breakdown. PLCs transformed automation when converting control to a digital form and permitting easy programmability.

More Technical Detail

In order to truly understand why MCUs and PLCs are so complementarity, let’s look at a few fundamental theoretical distinctions:

Execution Environment

MCUs → Execute on bare-metal firmware or small footprint RTOS, optimized for minimum power consumption and task-oriented operations.

PLCs → Employ a cyclic scan model (scan → execute → update outputs), so you have deterministic and predictable control.

Programming & Logic

MCUs – C/C++ or MicroPython programmable, suitable for algorithm-intensive or custom applications.

PLCs → Programmed in accordance with IEC 61131-3 standards (Ladder Logic, Function Blocks, Structured Text) — aimed at control engineers, stress on reliability.

Communication Protocols

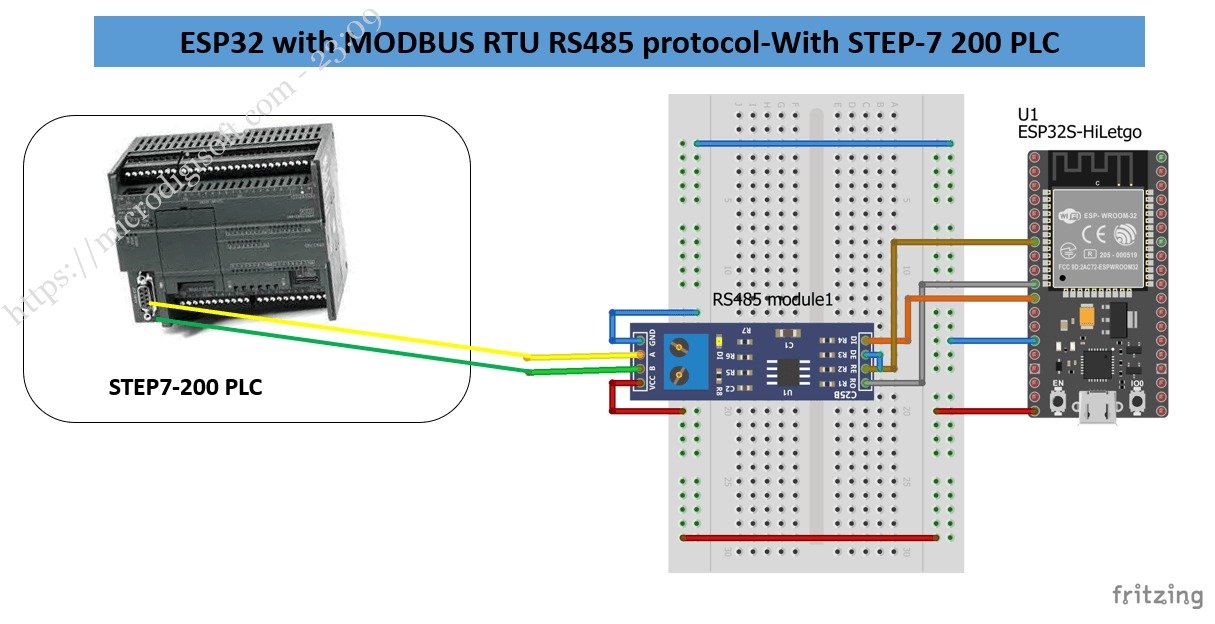

MCUs → Communicate to the world via I²C, SPI, UART, MQTT, Modbus RTU (most suitable sensors & IoT).

PLCs → Communicate over fieldbuses of industrial quality like EtherCAT, Modbus TCP (most appropriate for mission-critical real-time programs), PROF.

Reliability vs. Versatility

MCUs → Favor flexibility, economy, and innovation, though sometimes need additional precautions for robustness.

PLCs → Emphasize ruggedness, fail-safes, and adherence to safety standards (IEC/ISO), providing long-term uptime in rugged environments.

This is a natural matchup: MCUs have sensing and programmability, whereas PLCs have reliability and safety.

The Bigger Picture:

As the industries are transforming towards IoT, AI, and Industry 4.0, such distinction between MCUs and PLCs is vanishing.

MCUs are flexible, connected, and provide edge intelligence.

PLCs provide deterministic control, ruggedness, and safety compliance.

They collectively provide a strong automation platform — flexible, yet reliable.

Conclusion

Tomorrow’s automation is not a PLC nor an MCU matter. It is regarding MCU + PLC. From your watch to cities, this partnership is constructing the world in which we live — quietly, powerfully, and together.